Hello and Happy Christmas. It’s Boxing Day which, as all Jane Austen fans will know, did not exist in her day being a Victorian invention. Instead, in Georgian times, servants would traditionally be given the day off to either rest or travel to visit their families. This snippet was unearthed during a bit of research for my Pride & Prejudice sequel ‘Menace At Pemberley: Darcy & Lizzy’s First Christmas’.

For me, Boxing Day this year is a mixed blessing. Family who stayed over Christmas have sadly departed but, on the plus side, I can get back to writing the latest P&P variation, ‘Easter At Netherfield: Darcy’s Dice With Fate’ which I’m hoping to bring out about half way through January 2024. As usual, ‘Easter At Netherfield’ has required a lot of research.

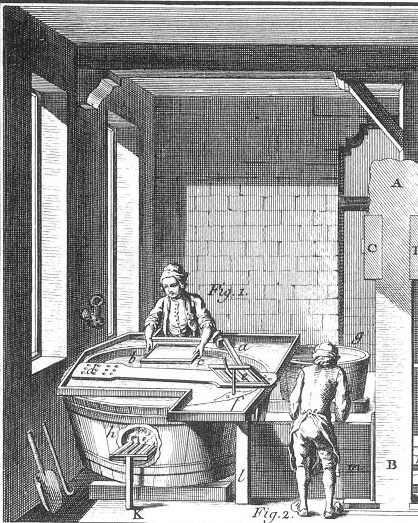

The book is set in 1799, and one of the major topics researched was papermaking as carried out in the late eighteenth century. At that time, the method for making paper by hand had not essentially changed for hundreds of years. Briefly, it involved the sorting of rags into batches for making various grades of paper, then ‘retting’ i.e. fermenting the rags in vats, after which the fermented rags were stamped to beat them into a pulp. In the late eighteenth century, the stamping devices were powered by water mills or windmills. Steam came a little later.

A rectangular mould with wire strung across it and a wooden frame fitted around it was dipped into the pulp and briskly shaken to level the pulp within and spread it to the edges of the mould which also caused the fibres to knit and bind together miraculously creating a sheet of paper. By about the middle of the eighteenth century, moulds of woven mesh had been developed by James Whatman of Turkey Mill near Maidstone in Kent which created a much smoother surface, hence the description ‘wove paper’. The sheets of papers were then stacked between sheets of felt and pressed, dried (by hanging them up) and then sized with gelatine made from boiling up animal parts.

Wood pulp for paper-making was not introduced until the nineteenth century due to its chemical properties being unsuitable without some treatment. Newspapers are still called ‘rags’ even today since rags were used for centuries as the raw material.

The size of paper produced by the above method was generally limited by the span of a man’s arms. At the Turkey Mill in Kent, much larger sheets were produced, though mainly for special orders, not routinely. The method involved a ‘contrivance’ developed by James Whatman II and eleven men to complete the whole process.

At about the end of the 18th century, a wire-cloth-covered cylinder machine was invented by a Frenchman and was subsequently improved upon at Frogmore Mill in Hertfordshire, which is still incidentally in existence as a heritage site. The machine enabled much longer lengths of paper to be produced and at about four times the speed of the hand-made sheets. Nonetheless, the machines were expensive and the hand-making of paper continued commercially for many years.

The method I’ve described above is of course a very abbreviated version indeed of how paper was made and many people who are familiar with the process will recognise this. The process was painstakingly skilled. Nonetheless, paper mills which made standard-sized sheets would, incredibly, produce two thousand sheets a day.

I am indebted to a Canadian paper historian and author for help and guidance she gave me in researching papermaking, for recommending a You Tube video which makes it possible to more easily understand the process and, in particular, for recommending two books which were immensely useful in explaining the workings of Turkey Mill which Darcy visits in ‘Easter At Netherfield’. The author, with her consent, is acknowledged by name in my ‘Author’s Note and Sources’ in ‘Easter At Netherfield’. The books she recommended are ‘James Whatman – Father and Son’ and ‘William Balston, Paper-Maker 1759-1849’ both by Thomas Balston. These two books between them as well as a few church records and other genealogical information sites provided most of the material for the chapter in which Darcy visits the Turkey Mill. It is so important when writing about real people and real places to have access to information about them and the books mentioned massively helped to bring these real eighteenth century people to life.

The attached image is “Papermaking. Plate X” taken from The Encyclopedia of Diderot & d’Alembert Collaborative Translation Project and shows an eighteenth-century vatman dipping the mould into the vat. (Image credit detail: CC BY-NC-ND 3.0)

Recent Comments